Boiler failure.

|

Reason for boiler Failure

|

Fire Tube

|

Water Tube

|

|

Mechanical, electricalfault/failure, maintenancetesting

|

35%

|

19%

|

|

Boiler water trouble

|

17%

|

36%

|

|

Personnel

|

16%

|

13%

|

|

Corrosion and erosion

|

11%

|

9%

|

|

Installation and designdeficiencies

|

10%

|

8%

|

|

Defective material

|

8%

|

3%

|

|

Other reasons-miscellaneous

|

3%

|

|

According to Factory and Machinery Act (Steam

boiler & unfired pressure vessel) regulation,1970:

Every steam boiler shall be provided with:1. Two or more Safety Valve

2. Two Water gauge

3. A steam pressure gauge

4. A blow down valve or cock

5. Two feed water pump

6. A main steam stop valve

7. A feed check valve

8. An inspector’s test pressure gauge attachment

9. A fusible plug

10. A low water alarm

11. A low water fuel cut out

12. Manufacturer’s name plate

13. Registration plate

Historically, boilers were a source of many serious injuries and property destruction due to poorly understood engineering principles. Thin and brittle metal shells can rupture, while poorly welded or riveted seams could open up, leading to a violent eruption of the pressurized steam. Collapsed or dislodged boiler tubes could also spray scalding-hot steam and smoke out of the air intake and firing chute, injuring the firemen who loaded coal into the fire chamber. Extremely large boilers providing hundreds ofhorsepower to operate factories could demolish entire buildings.

lA boiler that has a loss of feed water and is permitted to boil dry can be extremely dangerous. If feed water is then sent into the empty boiler, the small cascade of incoming water instantly boils on contact with the superheated metal shell and leads to a violent explosion that cannot be controlled even by safety steam valves.

Draining of the boiler could also occur if a leak occurred in the steam supply lines that was larger than the make-up water supply could replace.

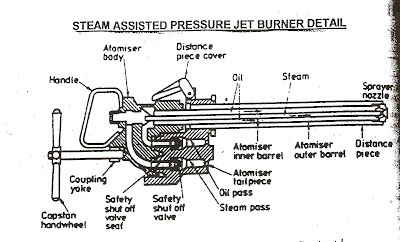

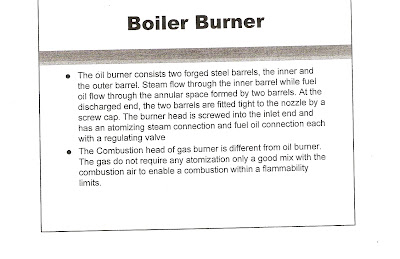

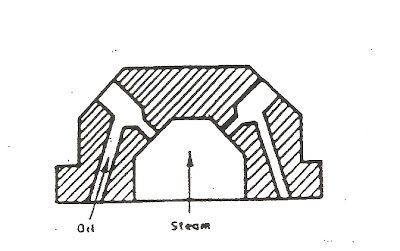

Burner

An oil burner is a heating device which burns fuel oil. The oil isatomized in to a fine spray usually by forcing it under pressure through a nozzle. This spray is usually ignited by an electric spark with the air being forced through by an electric fan.

Burner

An oil burner is a heating device which burns fuel oil. The oil isatomized in to a fine spray usually by forcing it under pressure through a nozzle. This spray is usually ignited by an electric spark with the air being forced through by an electric fan.

Flame and Smoke

-A yellowish orange, rolling flame indicates good combustion.

-An incandescent white flame with jagged edges shows excess air

-A reddish, smoky flame indicates insufficient air

oSmoke

-A light brown haze at the stake usually indicates efficientcombustion

-Black smoke at the stake usually indicates insufficient air

-White smoke at the stake indicates a large amount of excess air

A boiler is a closed vessel in which water is heated. Vaporized fluid (steam) exits the boiler

A closed former that is used to support stimulation at pressures that exceed atmospheric pressure, and includes superheater equipment and economizer and other equipment attached to it.

Draft

A. Draft provides the differential pressure in a furnace to ensure the flow of the gases. Without draft, stagnation in the burning process would result and the fire or process of combustion would die from lack of air. Draft pushes or pulls air and the resultant flue gas through a boiler and up into the stack. The draft overcome the resistance to flow of the tubes, furnace walls, baffles, dampers and the chimney lining.

Natural Draft

Natural draft is produced by the chimney into which the boiler exhausts. The cool air admit to the furnace, rushes in to displace the lighter hot gases in the furnace. Thus the hot gases rise (chimney effect), causing the natural draft.

Mechanical Draft

Mechanical draft is produced artificially by mean of forced or induced draft fans. The chimney is still necessary on mechanical draft installation for venting the produced of combustion high enough not to be offensive to the surroundings.

Entry into the Boiler

2.2. Ventilation and purging for 24 hrs (min 12 hrs)

3.3. Use oxygen analyser before entry

4.4. Carry out a bag of necessary tool

5.5. Enter the boiler with your head first ( vertical boiler: enter with leg first)

6.6. Remember to open top manhole first then follow up with bottom manhole cover (to prevent hot air to hitting you

Feedwater check valve

Fusible Plug is a threaded metal plug, usually of bronze, brass or gunmetal, with a tapered hole drilled completely through its length. This hole is sealed with a metal of low melting point, usually lead or tin. It is screwed into the crown sheet (the top plate) of a steam engine firebox, typically extending about an inch into the water space above. Its purpose is to act as a last-resort safety device in the event of the water level falling dangerously low: when the top of the plug is out of the water it overheats, the lead core melts away and the resulting noisy release of steam into the firebox serves to warn the operators of the danger before the top of the firebox itself runs completely dry.

Jasa perbaikan Boiler ,Jasa perbaikan Boiler cibitung, Jasa perbaikan Boiler Cikarang, Jasa perbaikan Boiler Cibinong, Jasa perbaikan Boiler Jakarta, Jasa perbaikan Boiler Cianjur, Jasa perbaikan Boiler Sumber, Jasa perbaikan Boiler Tarogong Kidul, Jasa perbaikan Boiler Indramayu, Jasa perbaikan Boiler Karawang, Jasa perbaikan Boiler Kuningan, Jasa perbaikan Boiler Majalengka, Jasa perbaikan Boiler Parigi,

Jasa perbaikan Boiler Purwakarta, Jasa perbaikan Boiler Subang, Jasa perbaikan Boiler Palabuhanratu, Jasa perbaikan Boiler Sumedang, Jasa perbaikan Boiler Singaparna, Jasa perbaikan Boiler Bandung, Jasa perbaikan Boiler Banjar, Jasa perbaikan Boiler Bekasi, Jasa perbaikan Boiler Bogor,

Jasa perbaikan Boiler Cimahi, Jasa perbaikan Boiler Cirebon, Jasa perbaikan Boiler Depok, Jasa perbaikan Boiler Sukabumi, Jasa perbaikan Boiler Tasikmalaya, Jasa perbaikan Boiler Rangkasbitung, Jasa perbaikan Boiler Pandeglang, Jasa perbaikan Boiler Serang, Jasa perbaikan Boiler Tangerang, Jasa perbaikan Boiler Cilegon, Jasa perbaikan Boiler Serang, Jasa perbaikan Boiler Tangerang, Jasa perbaikan Boiler Tangerang Selatan, Jasa perbaikan Boiler Banjarnegara, Jasa perbaikan Boiler Banyumas, Jasa perbaikan Boiler Batang,

Jasa perbaikan Boiler Blora, Jasa perbaikan Boiler Boyolali, Jasa perbaikan Boiler Brebes, Jasa perbaikan Boiler Cilacap, Jasa perbaikan Boiler Demak, Jasa perbaikan Boiler Grobogan, Jasa perbaikan Boiler Jepara, Jasa perbaikan Boiler Karanganyar, Jasa perbaikan Boiler Kebumen, Jasa perbaikan Boiler Kendal, Jasa perbaikan Boiler Klaten, Jasa perbaikan Boiler Kudus, Jasa perbaikan Boiler Magelang, Jasa perbaikan Boiler Pati,

Jasa perbaikan Boiler Pekalongan, Jasa perbaikan Boiler Pemalang, Jasa perbaikan Boiler Purbalingga, Jasa perbaikan Boiler Purworejo, Jasa perbaikan Boiler Rembang, Jasa perbaikan Boiler Semarang, Jasa perbaikan Boiler Sragen, Jasa perbaikan Boiler Sukoharjo, Jasa perbaikan Boiler Tegal, Jasa perbaikan Boiler Temanggung, Jasa perbaikan Boiler Wonogiri, Jasa perbaikan Boiler Wonosobo, Jasa perbaikan Boiler Magelang,

Jasa perbaikan Boiler Pekalongan, Jasa perbaikan Boiler Salatiga, Jasa perbaikan Boiler Semarang, Jasa perbaikan Boiler Surakarta, Jasa perbaikan Boiler Tegal, Jasa perbaikan Boiler Bangkalan, Jasa perbaikan Boiler Banyuwangi, Jasa perbaikan Boiler Blitar, Jasa perbaikan Boiler Bojonegoro, Jasa perbaikan Boiler Bondowoso, Jasa perbaikan Boiler Gresik, Jasa perbaikan Boiler Jember, Jasa perbaikan Boiler Jombang, Jasa perbaikan Boiler Kediri,

Jasa perbaikan Boiler Lamongan, Jasa perbaikan Boiler Lumajang, Jasa perbaikan Boiler Madiun, Jasa perbaikan Boiler Magetan, Jasa perbaikan Boiler Malang, Jasa perbaikan Boiler Mojokerto, Jasa perbaikan Boiler Nganjuk, Jasa perbaikan Boiler Ngawi, Jasa perbaikan Boiler Pacitan, Jasa perbaikan Boiler Pamekasan, Jasa perbaikan Boiler Pasuruan, Jasa perbaikan Boiler Ponorogo, Jasa perbaikan Boiler Probolinggo, Jasa perbaikan Boiler Sampang, Jasa perbaikan Boiler Sidoarjo, Jasa perbaikan Boiler Situbondo, Jasa perbaikan Boiler Sumenep, Jasa perbaikan Boiler Trenggalek,

Jasa perbaikan Boiler Tuban, Jasa perbaikan Boiler Tulungagung, Jasa perbaikan Boiler Batu, Jasa perbaikan Boiler Blitar, Jasa perbaikan Boiler Kediri, Jasa perbaikan Boiler Madiun, Jasa perbaikan Boiler Malang, Jasa perbaikan Boiler Mojokerto, Jasa perbaikan Boiler Pasuruan, Jasa perbaikan Boiler Probolinggo, Jasa perbaikan Boiler Surabaya, Jasa perbaikan Boiler bali, Jasa perbaikan Boiler kalimatan timur, Jasa perbaikan Boiler kalimantan,

Jasa perbaikan Boiler kalimantan barat, Jasa perbaikan Boiler pontianak, Jasa perbaikan Boiler banjar masin, Jasa perbaikan Boiler sulawesi, Jasa perbaikan Boiler bontang, Jasa perbaikan Boiler sorawako, Jasa perbaikan Boiler buton, Jasa perbaikan Boiler samarinda, Jasa perbaikan Boiler sarakan, Jasa perbaikan Boiler maluku, Jasa perbaikan Boiler NTB, Jasa perbaikan Boiler NTT, Jasa perbaikan Boiler Lombok, Jasa perbaikan Boiler Papua,

Jasa perbaikan Boiler Irian, Jasa perbaikan Boiler Tembagapura, Jasa perbaikan Boiler timika, Jasa perbaikan Boiler medan, Jasa perbaikan Boiler lampung, Jasa perbaikan Boiler Jambi, Jasa perbaikan Boiler nias, Jasa perbaikan Boiler padang, Jasa perbaikan Boiler aceh, Jasa perbaikan Boiler pekan baru, Jasa perbaikan Boiler bengkulu,

Jasa perbaikan Boiler palembang, Jasa perbaikan Boiler batam, Jasa perbaikan Boiler cilegon, Jasa perbaikan Boiler merak, Jasa perbaikan Boiler bajanegara, Jasa perbaikan Boiler cepu, Jasa perbaikan Boiler tuban, Jasa perbaikan Boiler dumai, Jasa perbaikan Boiler duri, Jasa perbaikan Boiler sulawesi, Jasa perbaikan Boiler sangkawang, Jasa perbaikan Boiler pangkal ambun, Jasa perbaikan Boiler sampit, Jasa perbaikan Boiler pare pare, Jasa perbaikan Boiler kalianda