COAL UPGRADING TECHNOLOGY FOR INDONESIAN LIGNITE.

Abstract

Strategic steps to promote the application of lignite upgrading technology in Indonesia have been discussed

Strategic steps to promote the application of lignite upgrading technology in Indonesia have been discussed. This paper provides thoughts and considerations for technological promotion processes that are in the process of commercialization. Drastic changes in energy supply and demand worldwide have prompted Indonesia to review current policies to anticipate changes in the coming years.

One of the fundamental changes is the increasing demand for coal, as long as coal is still considered the most economical fuel compared to other energy sources, even though the price of coal is still quite high following the price of fuel oil.

Because coal is the biggest potential in In the country, a very basic change in energy policy, especially regarding the utilization of low-rank coal, becomes very important considering that almost 70% of the total coal reserves of 57.8 billion tons are low-rank coal. Indonesia has been increasing the volume of coal exports per year despite the recent economic crisis.

Domestic demand for coal is still flat due to the economic crisis.

It is predicted that demand will increase because the fuel subsidy will gradually be phased out and coal is alternative energy.

It is predicted that demand will increase because the fuel subsidy will gradually be phased out and coal is alternative energy.

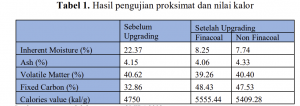

Given this situation, the promotion of coal upgrading technology should be accelerated. For this reason, it is necessary to select a technology that adheres to cost-effectiveness, is environmentally friendly and produces coal products with high calorific value, and is non-flammable. The results of the operation of the 5-ton-per-day pilot plant located in Palimanan, Cirebon, West Java, which is a joint project between Indonesia and Japan, to confirm the engineering performance of a continuous process is also the topic of discussion in this paper.

Introduction

Lignite is a kind of low-grade coal, which is formed by peat diagenetic formation of humic coal, it’s the lowest degree of coalification, always present brown, dark brown, dim, or asphalt luster color, no cohesive. Its physical and chemical properties are between peat and bituminous coal. High water content, high volatile, low density, containing humic acid, oxygen content up to 15 ~ 30%, easy to fragmentation, spontaneous combustion in the air.

According to China’s coal classification standards, they are divided into two categories: light transmittance PM 30 ~ 50% of the old lignite and PM less than or equal to 30% of the young lignite. Europa and Indonesian lignite are mostly old lignite.

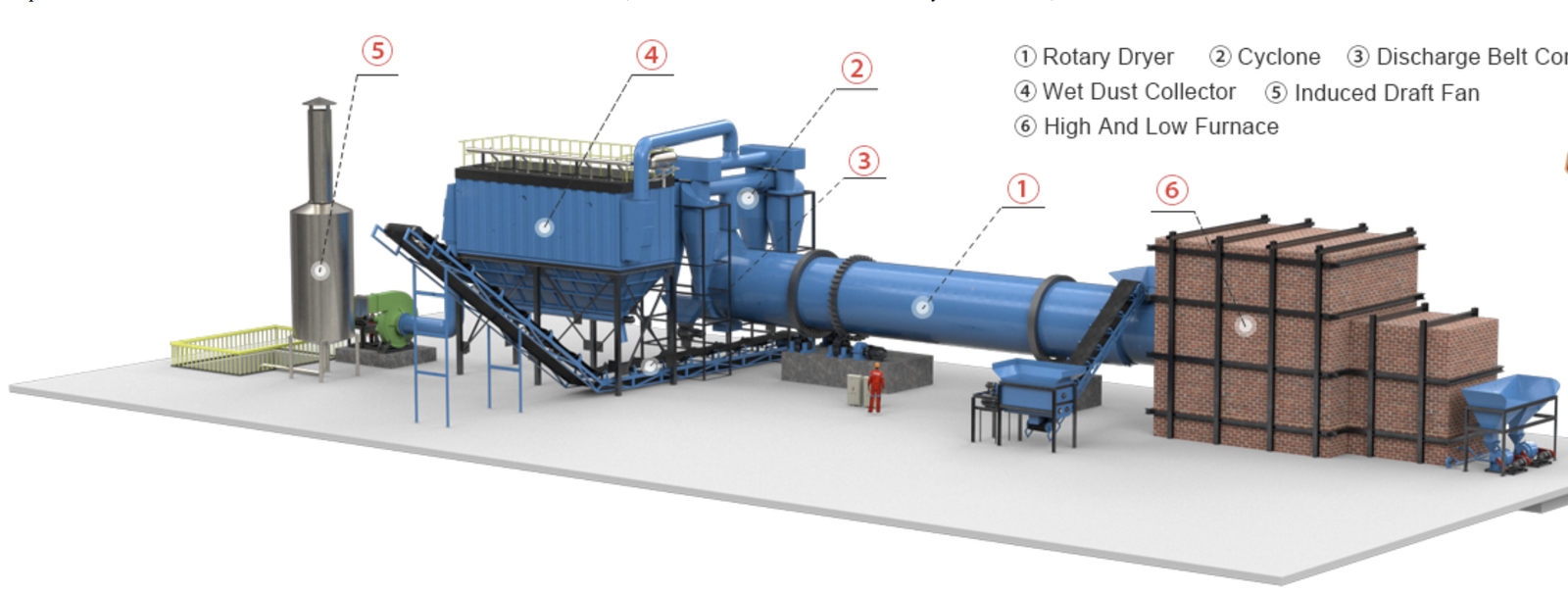

PT. Indira Dwi Mitra in the coal, coal slurry drying industry for many years, through the physical and chemical properties of coal and lignite drying temperature, pressure, airspeed, and oxygen quantity such related parameter research, establish lignite dryer test base in Inner Mongolia, after many experiments demonstrate the technology to research, successfully developed for lignite drying and lignite upgrade equipment.

Our company lignite dryer can reduce the moisture of lignite from 25-60% to 15-30%, after processing the calorific value of coal can reach 30-80%, direct as a substitute for thermal coal, bituminous coal, and anthracite used in power plants.

The technical equipment has been running in China’s Inner Mongolia, Yunnan, Xinjiang, and Indonesia, it is security, stable, energy conservation, and environmental protection, which has a huge potential market, suitable for various coal mining enterprises.

After several days of efforts by our after-sales installation team, the pulverized coal drying production line produced by our company has been officially installed and put into operation in Dalat Banner, Inner Indonesia. According to customer feedback, the operation effect is good, and PT INDIRA DWI MITRA pulverized coal dryer equipment has been High praise by customers.

Upgrading Coal Klin Dryer technology

The coal slime dryer equipment project carefully built by our company for Kalimantan customers has been installed and debugged and will be put into operation soon. This set of equipment was installed in Kalimantan central. Our technical engineers arrived at the customer site ahead of time and formulated a detailed installation plan based on the actual local situation. After the equipment arrived, the relevant installation and commissioning work was immediately put into operation.

Coal slime drying equipment is an independent research and development product of PT Indira Dwi Mitra. It not only has a number of technical patents, but also highlights its production capacity and energy-saving advantages in recent market performance, and has been widely praised and praised, especially in coal washing plants. good and wide application.

Workshop

Kawasan Pergudangan Laksana Business Park, Jalan Laksana 6 Blok F 09, Desa laksana Kec. Pakuhaji, Kab. Tangerang, Banten- 15570

PT Indira Mitra Boiler

Ratman Bejo

☎️081388666204

My Website

https://indira.co.id

Email: info@indira.co.id

Email: idmratman@gmail.com

https://www.youtube.com/@Ratman_Bejo/videos