Components of Water Pipe Boilers

Water Pipe Boilers

Understanding the parts of the boiler, will make it easier for us to understand the work process of the boiler. Boilers which are the media to “move” the heat energy content of fuel into water, have two major spheres of constituent components, namely components that support the combustion process, and components related to phase changes from water to water vapor. We will discuss both of these components one by one in this article.

As the subject of the discussion, I will take a reference in the form of a water pipe boiler with coal fuel (max capacity. 283 tons / hour of coal) and able to produce superheater water vapor max. 640 kg / s. This type of boiler is very commonly used in the steam power plant industry with max electricity production capability. 640 MW.

A. Water-Steam Side Boiler Components

The components of the boiler that I will mention below are components that are related to the process of phase change from water to water vapor. Water entering large-scale boilers has high temperatures and pressures. High temperatures are obtained from the preheating process , and are generated by pressure from the Water Pump Boiler Feed . Furthermore, the water will experience various processes in the boiler so that superheated steam is formed . And here are the parts of the boiler that are related to the process of changing the water phase:

- Steam Drum

As I explained in the previous article , Steam Drum in a boiler functions as a reservoir of a mixture of water and water vapor, and also functions to separate water vapor from water in the process of forming superheater vapor.

Working principle of Steam Drum

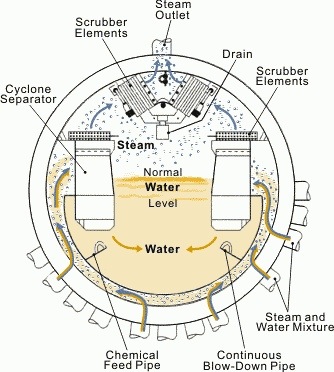

Steam drums have several inlets and two outlets. The water that enters the steam drum has a mixed phase between water vapor and liquid. In the steam drum there is a cyclone separator , this part serves to separate water saturated with water. Water vapor will come out through the upper pipe of the steam drum and head to the boiler to be heated further into dry steam. While the liquid phase is still going to the raiser tube to be heated so that the phase turns into steam.

Working Principle of Cyclone Separator

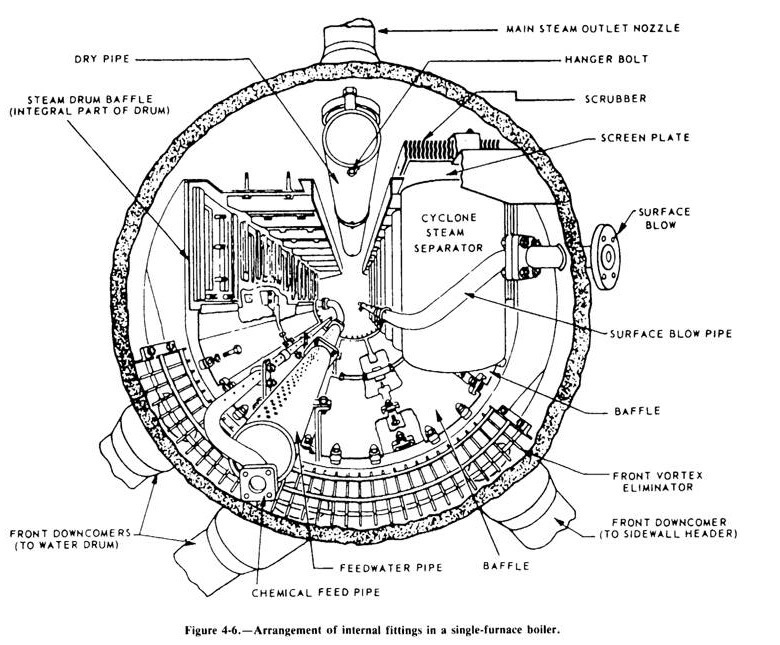

Cyclone separator is the main part in the steam drum . Inside the cyclone separator there is a kind of tilted disc that can rotate against its axis. A mixture of water vapor and pressurized water is pushed in so that it rotates. The effect of the rotation and impact of the fluid with the disc naturally separates water from saturated steam , so that the water will fall down while the water vapor will rise to the top. At the top of the steam drum output , there are sloping plates called eliminators / scrubbers . This plate also functions to separate water from steam so that only steam can pass through the scrubber .

Parts of Steam Drum

- Water Circulating Pump

Boiler Water Circulating Pump (BWCP) supplies water feedwater from the steam drum to the water wall / raiser tube . In sub-critical boilers, water can naturally flow in accordance with the boiler design, provided the pipeline is designed with very low barriers. The existence of BWCP will ensure that water fills all parts of the boiler pipe, which is not guaranteed to be done by boilers with natural circulation systems. Water circulation in the boiler is very important to note, because in addition to being a working fluid the water also functions as a cooling medium for boiler pipes. Just a little part of the boiler pipe is not filled with water due to the head drop BWCP output, it will be very fatal. - or example, let us consider one of the BWCP designs in a PLTU boiler above. The centrifugal pump is vertically positioned with one inlet and two outlets. BWCP uses a special electric motor with a pump. Between the pump and the motor, a sealing system such as gland packing or mechanical seal is not used , because the working temperature of the pumped water is too high. To overcome this, the rotor of the pump motor is designed to be submerged in water and a heat exchanger is used to cool the water inside the motor.

BWCP Parts

- Desuperheater

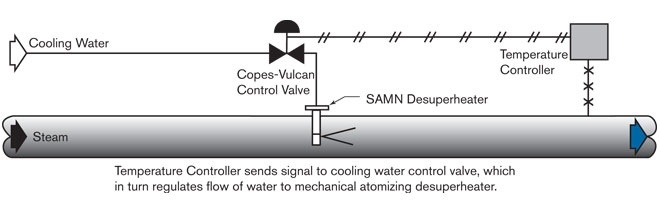

The superheater water vapor spray that enters the steam turbine in a power plant must have specifications in accordance with the provisions. Water vapor temperature must be maintained at a certain number so that it is in accordance with the requirements to drive a steam turbine. Desuperheater spray is a part of the boiler that functions to control the temperature of the superheater and reheater from the boiler by spraying water on it. The amount of water sprayed into the water vapor is controlled by the control valve. This component serves to keep the specifications of water vapor in the best parameters.

The Concept of the Desuperheater Spray System

The desuperheater system gets a signal input in the form of a water vapor temperature output system. This signal is processed so that the control system can adjust the control valve openings that supply water to the system. The water used must have a pressure greater than the water vapor pressure. Then water feedwater is used from Feedwater Pump Boiler outlets .

- pipe Boilers ( Tube )

Large-scale boilers are formed by pipes ( tubing ) measuring between 25 mm to 100 mm. These pipes have a special material and shape design that must withstand extreme temperature differences between the combustion chamber and the water / vapor flowing in it. In addition, pipe material must be a good conductor of heat, so heat transfer from the combustion process to water / steam can be effective.There are special designs on large boiler pipes that are quite unique. The pipes are threaded contoured in it, creating turbulent flow when water or steam flows inside the pipes. The purpose of creating turbulent flow is to reduce the friction effect between water or water vapor with the surface of the pipe, thereby reducing the risk of possible turbulence in the pipe grooves. In the end this will increase the efficiency of transferring heat energy from the combustion process to water.

Various sizes of pipe boilers

- Boiler Relief Valve

Boiler relief valve is a safety valve that functions to get rid of steam boiler when the pressure is too excessive above the boiler production conditions. This is to prevent a larger explosion that might be caused by a large superheater vapor pressure. Boiler relief valve has a certain working pressure that is in accordance with the predeterminedsetting before the boiler operates. If the boiler vapor pressure is greater than the working pressure of the relief valve, it will open and remove moisture into the atmosphere.