IDM Thermal Oil Heater Design

IDM Thermal Oil Heater Design

IDM Thermal Oil Heater Design

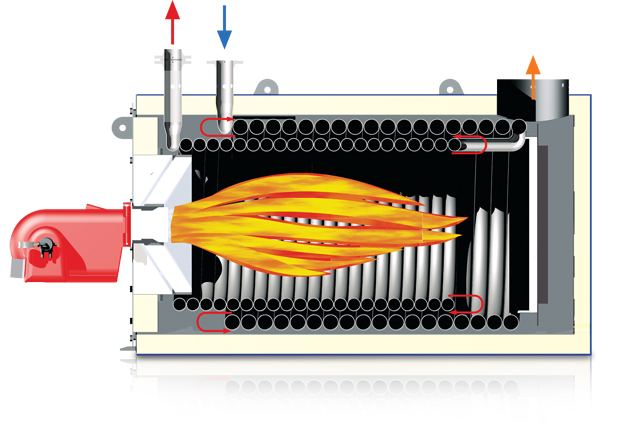

The pipe for the IDM Thermal Oil Heater is in a spiral shape, with the aim that the pipe surface is exposed to more heat from the burner in the heater. Rolled and sealed pipe will form a kind of wave due to the pipe surface, so that it can withstand hot air from the burner fire. So that the oil in the pipe is heated faster and the hot air will not be wasted because of these waves. This wave captures the fire continuously as long as the fire / hot air passes.

Coil pipe heater is made of 2 layers with certain gaps in each layer, and the inner layer is made with a more tenuous design so that hot air gaps enter the outer layer, so that it can enter the third fire. Basically, the TOH design is made like a steam boiler , because the principle is that many surfaces can be exposed to fire / hot gas from the burner. So that the fire gas flow design is formed into 3 passes. If it is less than that, a lot of energy / calories will be wasted, making fuel wasteful.

For external design, there is no specific shape which is a significant consideration, only based on operating comfort. For example, the position of the control panel is more likely to be simple affixed to the body oil heater, but some are stored in a separate support frame to better avoid body oil heater heat. For collecting tank, the placement was set higher with consideration of specific gravity at the surface boundary.

Workshop

Kawasan Pergudangan Laksana Business Park, Jalan Laksana 6 Blok F 09, Desa laksana Kec. Pakuhaji, Kab. Tangerang, Banten- 15570

PT Indira Mitra Boiler

Ratman Bejo

☎️081388666204

My Website

https://indira.co.id

Email: info@indira.co.id

Email: idmratman@gmail.com

https://www.youtube.com/@Ratman_Bejo/videos