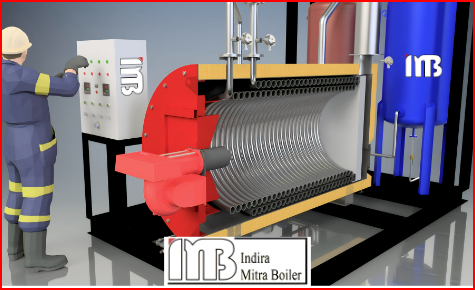

THERMAL OIL HEATER- PT INDIRA MITRA BOILER

Winsketel thermal Boiler

IDM Thermal Oil Heaters a heater using Thermal Oil Fluid as a heat conductor and can work up to a temperature of 300 degrees Celsius or more.

In contrast to steam which must use a pressure of up to 70 bar for the use of a temperature of 285 degrees Celsius, l only at the pressure of the circulation pump, so it is very safe and tools that require heating do not need to be designed with special construction.

The working life of the Thermal Oil Fluid used is generally more than 10 years and there is no need for any additions as long as there are no leaks in the pipes or heating equipment, and during that time no cleaning is needed because the inside of the heating coil is not crusty like in a Steam Boiler. Some of our IDM BOILER THERMAL Units are still working well at the age of more than 20 years.

What are the advantages of IDM Thermal Oil Heater compared to Steam Boiler?

Works at high temperatures with atmospheric pressure

Precise temperature controlboiler

No need for water treatment etc. chemicals that require high costs

There are no heat losses from condensate and blow down as in a steam boiler

No corrosion and crusting on the inside of the Boiler

Very low maintenance cost

Full Automatic and easy operation so it doesn’t require a special operator

Design

Thermoblock Oil is generally supplied in Vertical construction which saves space and is very efficient because it uses an Integrated burner that utilizes exhaust gas for preheating combustion air so that the oil combustion is very complete. Heating Coil is made of Seamless Boiler Tube which is rolled continuously. Each weld joint is carefully checked with a Radiaography Test and a final pressure test using a pressure of up to 30 Bar. Thermal Oil flows inside the coil at a speed that is carefully designed to avoid overheating which can cause oil damage due to the formation of charcoal (coking).

The hot gas from the combustion heats the flow of thermal oil in the combustion chamber as radiant heat and then heats the oil in the convection coil through the gaps between the coils at a certain speed in 3 passes in the opposite direction to the direction of the thermal oil flow. The turbulence generated by the gas as it passes through the coil results in an increase in the efficiency of the heater and a coil cleaning effect of soot that may adhere to the outside of the coil. Scope of Delivery: Each unit is supplied complete with accessories, including:

Heating Coil complete with cover

Circulation Pump

Expansion Tank & Deaerating Tank

Dashboard

Link Vidio Project

Workshop

Kawasan Pergudangan Laksana Business Park, Jalan Laksana 6 Blok F 09, Desa laksana Kec. Pakuhaji, Kab. Tangerang, Banten- 15570

PT Indira Mitra Boiler

Ratman Bejo

☎️081388666204

My Website

Email: info@indira.co.id

Email: idmratman@gmail.com

https://www.youtube.com/@Ratman_Bejo/videos