Mesin Air Kompresor

Maybe for you loyal readers of PT INDIRA MITRA BOILER, of course familiar with the name of the air compressor. If we are patching tires or going to a car or motorcycle repair shop, we will often see an air compressor. Even if we go to a dental clinic, sometimes we see a compressor too. Actually what is the main part of a wind or air compressor?

Maybe for you loyal readers of PT INDIRA MITRA BOILER, of course familiar with the name of the air compressor. If we are patching tires or going to a car or motorcycle repair shop, we will often see an air compressor. Even if we go to a dental clinic, sometimes we see a compressor too. Actually what is the main part of a wind or air compressor?

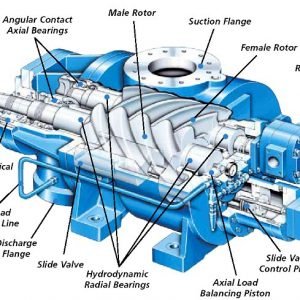

- Compressors have the name “Pumping Unit” which has the function to produce air pressure

- Then the compressor there is a motor (Activator) which has a role to drive the pumping unit, usually in the form of an electro motor.

- Then the last compressor has a tank, whose function is to accommodate the air produced by the pumping unit.

Then What Is The Right Way To Operate A Wind Compressor, Well Here Is The Explanation!

- Make sure the voltage used is appropriate, you should use an installation that uses “ground”

- After that install the air filter (intake filter)

- Next, fill the engine oil to taste, check the oil volume using “oil dipstick / oil glass” . When oil is at its maximum level, it means that the oil is in a sufficient state.

- Fully open the air outlet then turn on the switch in the “ON” position for about 10 minutes. After that close the drain back (the compressor remains in a state of ignition). The process of filling the tank with compressed air is ready. Then the needle on the pressure gauge on the “pressure gauge” will move to the maximum pressure level produced (example: 8 Bar). When the maximum pressure has been completed, the compressor will automatically shut down. And if the pressure decreases, the compressor will automatically turn on again automatically.

Then what types of compressors are usually sold in the market, so as not to be confused, I will explain the types of compressors based on the operating system.

TYPE OF WIND / AIR COMPRESSORS BASED ON THE MOVEMENT SYSTEM:

Direct Driven / Direct Coupling

The system used direct coupling air compressor is direct driven, where the driving motor is directly connected to the air pump. So that the number of rotations of the driving motor (rpm) automatically equals the speed of the air pump. Usually this type of direct driven compressor uses a motor with a speed of about 2,850 rpm and uses a single piston on the air pump. The advantage of this direct driven compressor type is that it is quite high at the speed of air delivery, because the air pump is rotated at a speed of 2,850 rpm. While the lack of direct driven type compressors is that the sound produced is so loud and noisy because it results from the high rotation of the air pump and also produces more water in the pressure tank.

Belt Driven

This type of compressor uses a connection system between the driving force and the air pump using a v-belt. Usually belt driven compressors are often encountered at tire patches. This air compressor is the most widely used compared to other types of compressors. Belt Driven compressors are capable of producing around 1500 rpm, so this compressor is more durable and durable compared to the direct driven type. The Belt Driven compressor itself is divided into 4 types, namely:

- Single Stage Air Compressor (Working Pressure 8 Bar, Maximum Pressure 10 Bar)

- Two Stage Air Compressor (Working Pressure 12 Bar, Maximum Pressure 14 Bar)

- High Pressure Air Compressor (Working Pressure Up To 14 Bar)

- Booster Air Compressor

TYPE OF WIND / AIR COMPRESSORS BASED ON LUBRICATION SYSTEM:

This type of compressor does not require lubrication for the piston. This compressor has advantages, namely the air produced is free of oil and the air produced is cleaner, but the disadvantage of this compressor is that it cannot work with weight. Generally this type of oil less compressor is widely used in equipment that is free of oil such as better painting, medical needs, for the food industry, etc.

Lubricated Compressor

Lubricated compressor parts such as piston drives require oil or lubrication

Now that we know the parts and also the types of air compressors, then how do I take care of the compressor so that it doesn’t get damaged quickly? Now here I share tips on how to care for a compressor that is good and right.

- Always clean the air filter or intake filter every week

- Lubricant replacement is done every use of 250 hours

- Routine to drain or clean the water deposits contained in the air tank after each use (maximum once a week)

- Clean the valve holder from dirt every 500 hours

- Always continue every month to clean the return valve

- After completing the compressor, it’s a good idea to clean the engine from dirt or dust

Every item or product we buy in the future will surely cause problems or damage to the goods. Similarly air compressor. So here I give some tips and solutions to the problems of wind compressors that often occur

The compressor cannot turn on

Cause:

- Power Source is Missing, Solution: Check the Power Source

- High Wind Pressure, Solution: Check Wind Pressure

- Use Overload, The Solution: Reset Overload

- Damaged Capacitors, The Solution: Replace Capacitors

- Damaged Motor, The Solution: Change Motor (Rewinding)

The compressor hums when it is turned on

Cause:

- Electric Voltage Too Low, The Solution: Install the Stabilizer

- Damaged Capacitors, The Solution: Replace New Capacitors

- Connecting Rod Jams, The Solution: Replace Connecting Rod

Compression None

Cause:

- Outlet Pipe Leaks, The Solution: Immediately Fix the Outlet Pipe

- Broken Valve, The Solution: Replace Valve

- Aus Piston Ring, The Solution: Replace the New Piston Ring

- Aus Piston, The Solution: Replace the Piston

- Beret Cylinder, The Solution: Replace the Cylinder

Rough Noise Compressor

Cause:

- Ball Bearings Are Damaged, The Solution: Replace New Ball Bearings

- Connecting Rod Holes Enlarge, The Solution: Change the Connecting Rod

Hopefully this article that I made, can provide enlightenment for those of you who currently want to have a compressor or even those who already have an air compressor.