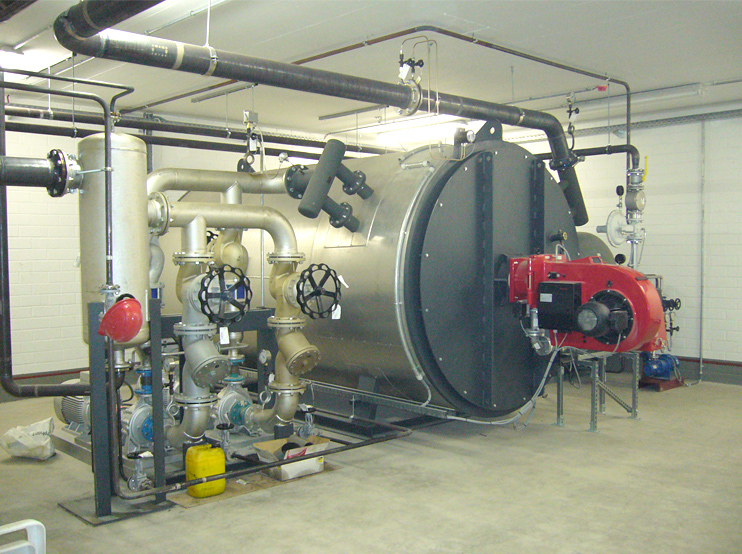

Hot Oil Heater Boiler, Winsketel

Indira Thermal is a thermal power plant using oil as a heating medium. Thermal Indira can be operated up to a maximum temperature of 350 oC with very low pressure (less than 5 bar), compared to using a steam boiler with the same operating temperature, the required pressure exceeds 70 – 80 bars.

Indira Thermal can be used in industries, Marine tanks, which require heat. Thermal Indira is designed with, vertical execution (standing position) and Horizontal execution (sleeping position). Multi tubular coils make the heat transfer in the coil very balanced and perfect, so it is more guaranteed to avoid the risk of burning the filming oil which can cause crust. The surface of the extra wide combustion chamber to avoid flames that can damage the surface of the coils.

Indira Thermal is assembled from a series of imported component materials that are known to be reliable and very high quality. Each component has a representative in Jakarta and is easy to get on the market so there are no worries about parts. Every manufacturing process is carried out according to strict standard procedures and Quality Control, making IndiraThermal a sturdy and reliable Oil heater.

Perfect handling and supported by good service and supported by professional technicians is a guarantee of the quality of this product. Free of import procedures, the delivery schedule can be adjusted to the needs of the customer with an integrated production process system. After sales guarantee, free commissioning and start up fees

Indira Thermal Construction The Indira Thermal Agency is the core of an oil heater. The inside is made of a multi helical coil system and at the end of the coil is joined in two headers as the inlet and outlet of hot oil. IndiraThermal coil construction is made using international standard boiler pipes that are rolled with pipe bending mechine without using heating so that it does not damage the chemical structure of the pipe material. On the outside the body of IndiraThermal is isolated by using rock wool to increase efficiency and coated with plate / aluminum foil as a wall on the outside. IndiraThermal is equipped with a control panel that is useful to facilitate the operator in operating IndiraThermal.

Expantion Tank Expantion Tank Expantion Tank is a combination of Deaerator tank, buffer tank and Expantion tank. With the unique combination of these three tanks, the topmost layer of oil associated with air will always be cooler so that the chance of oil oxidation is greatly reduced. Expantion tanks function to accommodate the expansion of heating fluid, remove air that is trapped in the Installation and prevent capitation in circulating pumps.

Expantion Tank Expantion Tank Expantion Tank is a combination of Deaerator tank, buffer tank and Expantion tank. With the unique combination of these three tanks, the topmost layer of oil associated with air will always be cooler so that the chance of oil oxidation is greatly reduced. Expantion tanks function to accommodate the expansion of heating fluid, remove air that is trapped in the Installation and prevent capitation in circulating pumps.

Circulation Pump Circulation pump serves to drain heating fluid in the installation. size and pump capacity are adjusted to Indira thermal design. Pump capacity determines the shape of the flow of heating fluid in the coil. The flow inside the hermal Indirat must be turbolent, this is useful to avoid damage to the heating fluid and coil in the hermal Indirat body. The circulating pump can operate up to a max temperature of 350 oC.

Control Panel The control panel is the central control of IndiraThermal. On this panel there are several switches and lights to operate the burner and circulation pump automatically. On the control panel there are also instruments and indicators that serve to regulate, set point monitor and control Indirat hermal. The control panel at IndiraThermal.

Safety Device Digital temperature controls., Low controls switch, Automatic burner controls Chimney temperature control, Pressure gauge, Pilot lamp indicator, Alarm How it Works IndiraThermal to the hermal Indirat body then process and return to the expantion tank. After the circulation flow of the heating fluid is stable, the burner will ignite and burn the coil in the hermal Indirat body so that the heating fluid becomes hot and the heat is flowed into the process. After the desired temperature is reached then the burner will automatically turn off and will turn back on after the temperature drops.Workshop

Kawasan Pergudangan Laksana Business Park, Jalan Laksana 6 Blok F 09, Desa laksana Kec. Pakuhaji, Kab. Tangerang, Banten- 15570

PT Indira Mitra Boiler

Ratman Bejo

☎️081388666204

My Website

https://indira.co.id

Specialist Fabrikasi,Thermal Oil Heater,Steam Boiler,Hot Water Boiler

Our Contact

IMB Product

Email: info@indira.co.id

Email: idmratman@gmail.com

Expantion Tank Expantion Tank Expantion Tank is a combination of Deaerator tank, buffer tank and Expantion tank. With the unique combination of these three tanks, the topmost layer of oil associated with air will always be cooler so that the chance of oil oxidation is greatly reduced. Expantion tanks function to accommodate the expansion of heating fluid, remove air that is trapped in the Installation and prevent capitation in circulating pumps.

Expantion Tank Expantion Tank Expantion Tank is a combination of Deaerator tank, buffer tank and Expantion tank. With the unique combination of these three tanks, the topmost layer of oil associated with air will always be cooler so that the chance of oil oxidation is greatly reduced. Expantion tanks function to accommodate the expansion of heating fluid, remove air that is trapped in the Installation and prevent capitation in circulating pumps.