Vertical Steam Boiler for Industrial Use – High Efficiency & Compact Design

If you’re looking for a compact, high-efficiency steam boiler for industrial applications, a vertical steam boiler is a smart choice. These boilers are designed for ease of installation, minimal space usage, and stable steam output, making them ideal for sectors such as food processing, pharmaceuticals, textiles, and more.

This article explores the main components, benefits, and technical insights of vertical steam boilers, particularly the LSS series, which ranges from 500 kg/h up to 2000 kg/h.

Also see our horizontal boiler products on the Other Products page

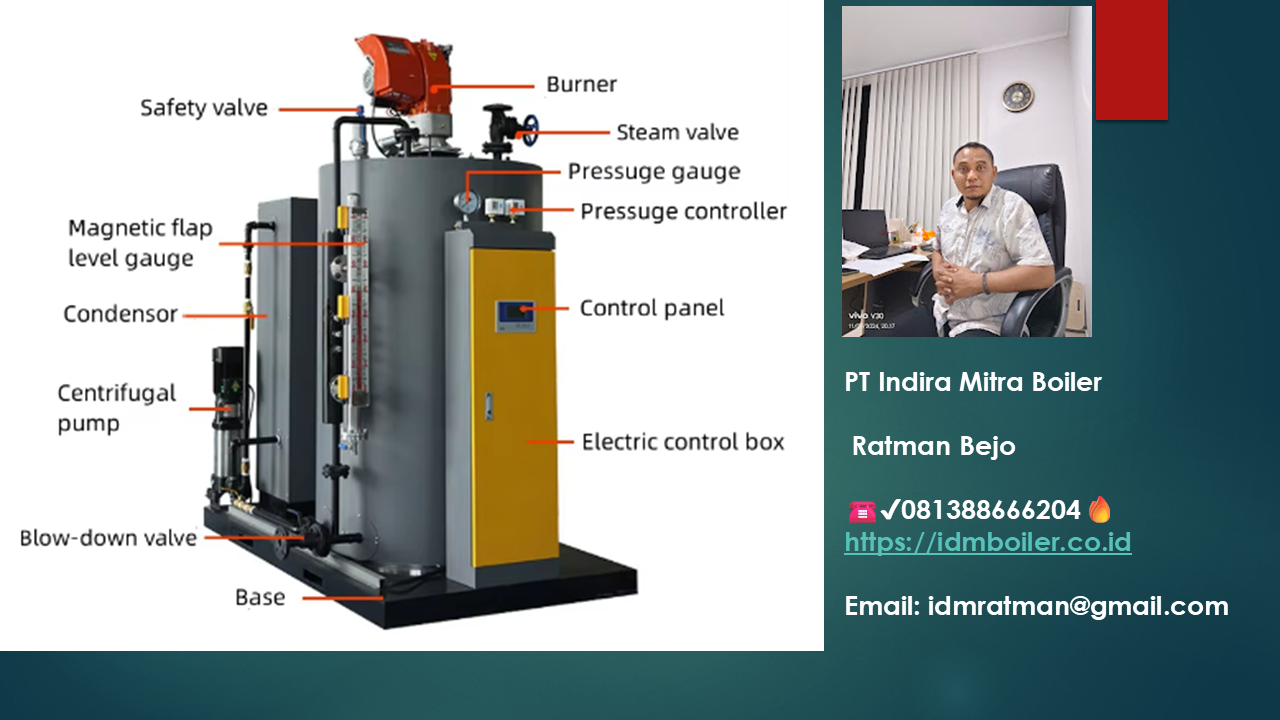

Key Components of a Vertical Steam Boiler (Based on Product Image)

Here are the main components typically found in a vertical steam boiler system:

-

Burner: Responsible for fuel combustion, typically using gas, diesel, or LPG.

-

Safety Valve: Ensures the boiler doesn’t exceed safe pressure levels.

-

Steam Valve: Controls steam output to the system.

-

Pressure Gauge: Displays real-time internal steam pressure.

-

Pressure Controller: Automatically adjusts pressure to maintain safety.

-

Control Panel: Interface for monitoring and managing the boiler’s operations.

-

Electric Control Box: Houses electrical systems and automation.

-

Magnetic Flap Level Gauge: Displays water level within the boiler.

-

Condenser: Increases efficiency by condensing unused steam.

-

Centrifugal Pump: Circulates water into the boiler chamber.

-

Blow-Down Valve: Releases sediment and waste water from the system.

-

Base: Supports the full structure and ensures proper alignment.

⚙️ Technical Benefits of Vertical Steam Boilers

1. Space-Saving Vertical Design

Vertical boilers occupy a smaller footprint compared to horizontal models, ideal for facilities with limited space.

2. High Combustion Efficiency

Modern burners ensure complete fuel combustion, improving thermal efficiency while reducing emissions and fuel costs.

3. Multi-Fuel Options

Supports a range of fuels including:

-

Natural gas

-

Diesel oil

-

Liquefied Petroleum Gas (LPG)

4. Automatic Control System

With integrated electric control panels and pressure controllers, the boiler can operate with minimal human intervention.

5. Reliable Steam Output

Stable and consistent steam production supports critical industrial processes.

Application Areas

Vertical steam boilers are widely used in various industries:

-

Food & Beverage: Sterilization, cooking, canning

-

Textile: Dyeing, ironing, and finishing

-

Pharmaceutical: Sanitation, chemical reactions

-

Chemical Industry: Process heating and cleaning

-

Commercial Laundry: Steam pressing and drying

Available Capacity & Specifications (LSS Series Overview)

| Model | Steam Output (Kg/h) | Working Pressure (MPa) | Fuel Type | Power (BHP) |

|---|---|---|---|---|

| LSS0.5 | 500 | 0.8 | Gas/Diesel/LPG | 32 |

| LSS0.8 | 800 | 0.8 | Gas/Diesel/LPG | 51.2 |

| LSS1.0 | 1000 | 1.0 | Gas/Diesel/LPG | 64 |

| LSS1.5 | 1500 | 1.0 | Gas/Diesel/LPG | 96 |

| LSS2.0 | 2000 | 1.0 | Gas/Diesel/LPG | 128 |

All models are built for easy maintenance, low operational costs, and long service life.

️ Maintenance Tips

-

Check water levels using the magnetic gauge daily.

-

Blow down the system regularly to remove sediment buildup.

-

Inspect safety valve and pressure gauge monthly.

-

Clean the burner every 3–6 months for optimal fuel efficiency.

✅ Why Choose a Vertical Steam Boiler?

✔ Ideal for limited-space facilities

✔ Automated operation with digital control

✔ Versatile fuel options

✔ Low emissions and energy-efficient

✔ Suitable for both small and mid-scale industries

Burners Control Systems for Industrial Boilers

Contact Us

Looking for the perfect vertical steam boiler solution for your industrial facility?

Contact our technical sales team today to request a quote or get more details about the LSS series.

PT Indira Mitra Boiler

Ratman Bejo

☎️✔081388666204