Brew Kettle Direct-Fired Made of SS316L with Burner – Fabricated by PT Indira Mitra Boiler

What is a Direct-Fired Brew Kettle?

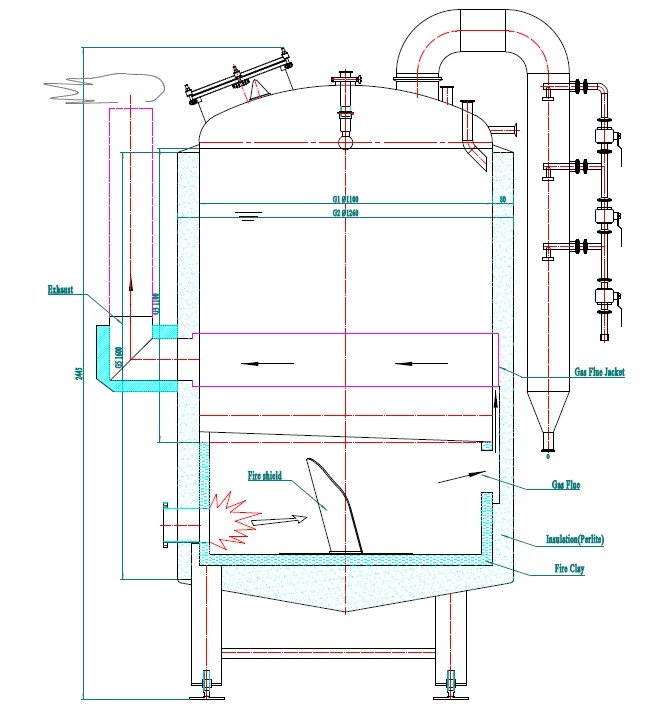

In the brewing industry, the brew kettle is one of the most essential pieces of equipment. A direct-fired brew kettle uses an open flame from a burner to heat the wort directly through the bottom of the tank. This stage is critical in determining the quality, flavor, and consistency of the final beer.

PT Indira Mitra Boiler, a leading fabricator in Indonesia, manufactures direct-fired brew kettles made of SS316L stainless steel with burners. Designed with food-grade material, advanced heating systems, and strict fabrication standards, our brew kettles provide efficiency, hygiene, and reliability for breweries of all sizes.

Why Use SS316L for Brew Kettles?

The choice of material plays a crucial role in brewery equipment. PT Indira Mitra Boiler uses SS316L stainless steel for several reasons:

-

Food grade quality → safe for direct contact with beverages.

-

Corrosion resistance → ideal for humid and chemical-rich brewing environments.

-

Smooth and easy-to-clean surface → supports CIP (Clean in Place) systems.

-

Durability → withstands high temperatures and repeated brewing cycles.

SS316L stainless steel is the global standard for brewery, dairy, and pharmaceutical applications.

Direct-Fired System with Burner

The direct-fired system uses a gas burner (such as Baltur or Riello) that produces a stable flame directly under the kettle.

Advantages of the direct-fired system:

-

Fast heating – the flame contacts the kettle bottom directly.

-

Energy efficient – modern burners ensure reduced gas consumption.

-

Precise control – equipped with automatic temperature sensors.

-

Consistent brewing results – fire shield/refractory distributes heat evenly.

Key Components:

-

Gas Burner (Baltur/Riello) – reliable heat source with adjustable flame.

-

Fire Shield/Refractory – protects the kettle bottom from direct flame damage.

-

SS316L Brew Kettle Tank – hygienic vessel for wort boiling.

-

Insulation layer – maintains thermal efficiency and prevents heat loss.

PT Indira Mitra Boiler as a Professional Fabricator

As a trusted brew kettle fabricator, PT Indira Mitra Boiler offers:

-

Custom design engineering according to brewery needs.

-

Fabrication of SS316L stainless steel kettles with food-grade finishing.

-

Installation of gas burners (Baltur, Riello, or equivalent).

-

Application of refractory/fire shield for heat distribution and protection.

-

Hydrotest and quality control to ensure product reliability.

-

On-site installation and commissioning.

Applications of Brew Kettle Direct-Fired

Our kettles are widely used in:

-

Large-scale breweries for commercial beer production.

-

Craft breweries focusing on small batches and unique flavors.

-

Fermented beverage industries such as cider, kombucha, and herbal drinks.

-

Food industries requiring hygienic liquid heating (milk, juice, sauces).

Advantages of PT Indira Mitra Boiler’s Brew Kettle

-

Premium SS316L stainless steel → long-lasting and food grade.

-

High-performance burners → stable and efficient heating.

-

Flexible capacities → from 200 liters to 10,000 liters or more.

-

Hygienic design → supports CIP systems, easy maintenance.

-

Competitive pricing → local fabrication with international quality.

Fabrication Process at PT Indira Mitra Boiler

-

Engineering design → calculate capacity and process requirements.

-

Cutting and welding SS316L → TIG/MIG methods for food-grade quality.

-

Burner and refractory installation → ensure heating efficiency.

-

Quality control and NDT testing if required.

-

Hydrotest and commissioning → verify performance and safety.

Maintenance & Service

We provide after-sales services such as:

-

Refractory/fire shield replacement.

-

Burner service (Baltur, Riello).

-

Temperature control calibration.

-

Cleaning and inspection of SS316L tanks.

Why Choose PT Indira Mitra Boiler?

-

More than 10 years of experience in boiler and industrial fabrication.

-

Skilled engineers and certified welders.

-

Custom fabrication for breweries of any scale.

-

Strong after-sales service.

-

Competitive and transparent pricing.

Contact Us

For brew kettle direct-fired made of SS316L with burner, trust PT Indira Mitra Boiler.

Hubungi Kami

PT Indira Mitra Boiler

Ratman (Sales Engineer)

☎️✔081388666204

Email: info@indira.co.id

Email: idmratman@gmail.com