Preliminary Study of Bubble Study on Measured Sentripugal Pumps

With Vibration Signals

Abstract

Cavitation occurs when the fluid flowing is in the area undergoing change pressure quickly. Cavitation is defined as the formation of deep empty cavities fluid flow and then rupture. The occurrence of cavitation is one of the causes

sudden drop in pump performance and instability in operation will a problem in working the pump. The indication of cavitation at the pump is high vibration and noise and damage to pump components.

Wrong one cause of vibration occurs as a result of the emergence of the bubble phenomenon (Popr < Saturated steam). The purpose of this study is to examine the Bubble Characteristics as initial indication of the occurrence of the Cavitation Phenomenon by using vibration signals. The methodology used is by varying the capacity with

use the valve to vary the openings so that a bubble phenomenon occurs. Size the bubble that arises is photographed so that it can know the effect of the large capacity happened, then also from the amount of NPSHA and reynold number to be as parameter. This method is expected to define the bubble phenomenon with the magnitude of the vibrations that arise.

From the results of the study showed that the resulting bubble occurred a large amplitude with a larger vibration signal shown at low capacity and the greater the capacity, the smaller the vibrations that arise the head gets smaller. Identification of cavitation begins with the emergence of a bubble occurs in the suction pipe at an acceleration value of 0.305 m / s2 in the horizontal direction, 0.242 m / s2 in the vertical direction and 0.245 m / s2 in the axial direction. Keywords: centrifugal pump, bubble, cavitation, suction pipe.

1. INTRODUCTION

1.1 Background The pump is one the hydraulic fluid flow engine serves to move fluid no incompressible fluids from somewhere to another place with how to increase the fluid pressure moved it. Centrifugal pumps are kind pumps that are very widely used by industries mainly processing and water distribution works with principle of impeller rotation as an element fluid displacement driven by a starting driver.

Liquid substances will rotates due to blade pushes and give rise to the centrifugal force causing fluid to flow from middle of the impeller and out through blades and leave high speed impellers. This high speed liquid passed that channel the crossing is getting bigger so that head changes occur (high press) speed to head pressure. After the liquid is thrown by the impeller, the space between the blades become vacuum, causing liquid will be sucked in so that it happens suction process.

Pay attention to this and with the breadth of application usage this centripugal pump, it is needed high stability and performance very good and can reliable, and when it falls sudden pump performance

in surgery is often a problem and interfere with system performance whole. Decrease in performance

pump suddenly and instability in the operation will a problem, an indication of the cause the decrease in pump performance is one of them is caused by cavitation (cavitation). Cavitation is defined as formation of deep empty cavities a liquid with high forces and then it breaks, this cavitation occurs when the liquid is at areas that have changed pressure quickly. This phenomenon very dangerous and known as a phenomenon that is of a nature

damage to important parts pumping instrument and lowering the performance of the pump itself. In the case of this cavitation the pump section who often experience cavitation is suction side of the pump. This happens if the pump suction pressure is too low to under saturated vapor pressure.

Research and Testing to cavitation at the pump is very interesting so it has a lot carried out by several researchers and testing center to test and several several causes from different aspects including are:

J. Jeremi and K.Dayton (2000) which detects cavitation where experiments carried out on a centrifugal pump, the cavitation phenomenon in detection by pressure monitoring dynamic entry on the inlet. This research can be used as an initial indication of occurrence cavitation at the pump with the appearance of noise and this method can be used to find out seal wear. Theodorus Bayu Hanandoko (2000), conducted a study the symptoms that appear to the process of cavitation, this study describes the parameters which consists of noise, vibration, decline in performance and occurrence impeller damage as a result cavitation. Gultom D (2001) has researched influence pressure and temperature against cavitation. This research illustrates the influence of pressure and temperature.

Suyanto, Irham (2007), conduct experimental study the cavitation phenomenon on the pump blade centrifugal. In this research parameters used for observing is the Thoma number (σ), and the results obtained by cavitation on the centrifugal pump blade the intensity is getting bigger at low cavitation rates caused by low suction pressure,

high fluid temperature, capacity and big round. Bruno Schiavello and Frank

C. Visser (2009) has do research on the influence of NPSHR and NPSHA resulting in cavitation, in this study described the influence of NPSHR and NPSHA the age of the impeller. Thus also research conducted by Richmond (2006) by doing testing of centripugal pumps with operational conditions the different observed is vibration

which is measured in the direction different. The observed is air bubbles caused.

By reviewing research about bubble from research that has been done by some previous researchers, authors

trying to do research against the bubble by doing observation of bubbles and vibration caused.

1.2 Problem Formulation

Cavitation that occurs due to rupture bubble-bubble by number and dimensions of various sizes accompanied

with the onset of vibration. Occurrence changes in flow types in pipes and pressure change, that pressure

happens to reach vapor pressure so resulting in air bubbles which flows to the side entered in impeller area, bubbles will be carried away by fluid flow and entering on more pressure area high, so the bubbles will broke and caused noise and specific vibrations occur.

1.3 Research Objectives

1.3.1 General Purpose of Research

The general purpose of this study is monitoring bubbles arises in the impeller area resulting in a vibration specific, vibration measurements done using signals vibration vibrations by varying valve to get variation incoming capacity in the suction pipe.

1.3.2 Specific Objectives of Research

Analyze the phenomenon of cavitation by using vibration signals so that the relationship can be known vibration characteristics with Bubble characteristics.

1.4 Benefits of Research

The benefits of this research are:

1. Providing information about application of techniques

vibration identification and cavitation in impellers.

2. Vibration signals can be made as a reference for cavitation as a result of bubbles broken due to occurrence

difference in pressure in the work area impeller.

1.5 Scope of Research

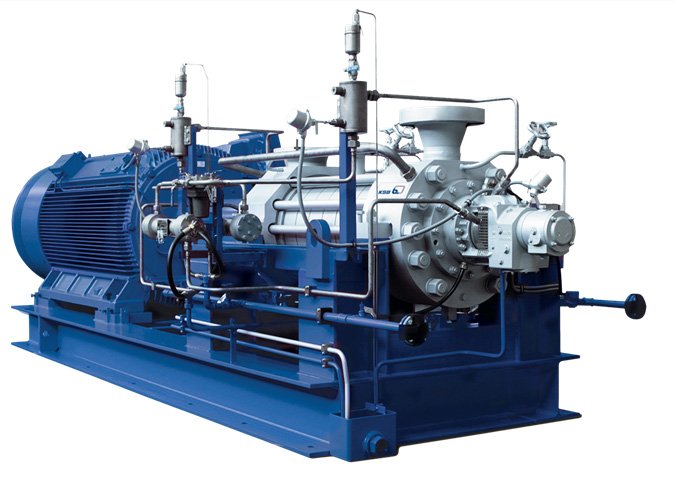

This research was conducted with the way of the experimental method with use a centrifugal pump Aquavane KSB Type A32-160 with capacity of 3.5 liters / s and rounds of 1450 rpm. For pumps with types centrifuges have been investigated by researchers previously between like tables below this:

Based on the roadmap from the researcher before, this study did observation of bubble and change in gasoline is the beginning the occurrence of the cavitation phenomenon in the area impeller using the casing which has been made a gap that is closed with acliric ingredients, making slits intended to be observed visual bubbles that occur.

Casing This transparent function besides as the pump casing is also used to observe visually buble arising as well as changes in dimensions of these bubbles. This observation done using high-speed digital camera, then at the same time carried out measuring vibrations with vibration signal.

2. LITERATURE REVIEW

2.1 Characteristics of Pumps The pump has a main function among them is circulating fluid around the system and move it fluid from place to place others by increasing pressure the fluid.

Because the pump shaft rotates, then the impeller with blades the impeller rotates so that the pressure and speed up and thrown from middle of the pump to the drain volute or equal and Dynamic Journal, Volume I, No.11, June 2012 ISSN 0216-7492 4 channeled out through the nozzle.

The good of a performance the pump depends on the characteristics from the pump itself. The characteristics of the pump are pump performance in graphical form relationship between Head, power and Efficiency towards debit. Characteristics from a centripugal pump is a way where the differential pressure is high varies with output at constant speed.

Head and flowrate

determine the performance of a pump which is graphically in the form of a curve performance or pump characteristic curve. Debit flow at a particular head is called task point. Pump performance curve is made from many task points. Operating point the pump is determined by intersection system curve with the pump curve as shown in the picture below this In the picture above In this research pump used is the Aquavane pump is the result of research

done by previous researchers , below is a high pressure curve indicated as capacity capacity increase in total height press happened to the pump in this case is the Aquavane pump shown in the picture below.

2.1.1 Total static head

Total static head is is a high difference between surface of the liquid on the press side with the surface of the liquid on the side suction.

2.1.2 Total Pump Head

The total head of the pump must be provided for flowing volume water fluid as planned can be determined by installation conditions the pump itself.

2.1.3 Loss Head

In pipe installations there are head loss, this is because friction and equipment pipe between valves, turns,

constriction or enlargement sudden cross section so that turbulence occurs. Head losses can be divided into 2

kinds, namely major head loses and minor head losses.

As for total losses from the installation is addition of major head with head minor. Next to the flow laminar and turbulent are available different equations, as benchmark whether a flow is laminar or turbulent numbers are used

Reynolds.

2.1.4 Net Positive Suction Head (NPSH) The NPSH parameter shows the difference between the actual pressure

liquid in the pipe and vapor pressure liquid at a certain temperature. NPSH is an important parameter

to consider when designing a circuit. Every time decrease in fluid pressure below

vapor pressure, the liquid will boil happens and the final effect will occur cavitation so bubbles occur

can reduce performance from pump.

So that the pump can work without experiencing cavitation, it must be fulfilled more available conditions greater than NPSH used NPSHA (available)> NPSHR (required)

2.2 Vibration Analysis

Motion analysis is is one method very appropriate to determine initial prediction of a problem in machinery, this can be early predictions of damage will happen to engine parts that is. Vibrating structure or oscillates because the force varies based on time. Deep vibration the structure of the results of energy transformation potential to potential nergy to energy kinetic or vice versa. Energy the potential in the structure is determined by elastic elements, while energy

the kinetic is determined by the element mass. Movement in the engine and the structure is not expected because of

raise voltage and will reduce its energy.

All objects that have mass and elasticity can vibrate, so most machines and structures experience vibration to a certain degree and the design usually requires consideration of its oscillation

2.2.1 Characteristics of Vibration

Condition of a machine and mechanical problems that occur can be known by measuring vibration characteristics on the engine that is. Characteristics important vibrations include :

a. Vibration Frequency;

b. Transfer Vibration (Vibration Displacement);

c. Vibration Speed (Vibration Velocity);

d. Acceleration of Vibration (Vibration Acceleration);

e. Vibration phase

2.2.2 Harmonic Vibration

Harmonic vibration is motion back and forth objects through a point certain balance with the amount of vibration of objects in each seconds are always the same. Each component the vibrating has perodic motion.

2.3 Kavitation and Perististiwa

the occurrence of Bubble The term Cavitation comes from the word greek which means empty space or cavity. Webster’s dictionary define cavitation as rapid formation and collapse cavity in the liquid flowing in very low pressure area, so cavitation is an event steam bubble formation in in liquid that is flowing because the liquid pressure decreases until under saturated vapor pressure liquid at the pump operating temperature, below can be seen the process cavitation

Figure 2.11 Cavitation

The occurrence of cavitation symptoms occurs because of the liquid vaporizes is flowing in the pump or outside the pump, because of the pressure reduced to under pressure saturated vapor when the liquid boils, the bubble bubble will emerge liquid. Pressure drop on centrifugal pumps in general caused by several things, between

others:

1. Increase the static lift force from centrifugal pump

2. Decreasing atmospheric pressure together with increasing elevation / elevation

3. Decreased absolute system pressure, as found in pumping fluid from a vacuum tube.

4. Increase in fluid temperature pumped up.

From this phenomenon, it can be clear look, cavitation at this pump will threatening the surface / entrance side

from the impeller so it will reduce the performance of the pump this, because of the occurrence static pressure reduction with value under liquid vapor pressure. Static pressure in the suction system external occurs mainly due

friction in the suction pipe. And reduction in internal static pressure internal suction system occurs mainly caused by an increase in the eyes impeller. In general, it can be concluded that cavitation will occur resulting in several losses

as follows :

1. Decreasing head and capacity pumping

2. Decrease pump efficiency

3. Rupture of steam bubbles when through pressure areas higher will cause noise, vibration and damage to some

components especially impellers and diffuser.

Cavitation divided into

4 (four) kinds of centrifugal pumps based on the cause, namely:

1. Cavitation in suction (Suction cavitation).

2. Recirculation Cavitation.

3. Incipient Cavitation

4. Vane passing Syndrome Cavitation

2.3.1 Characteristics of Bubble As stated before, cavitation was a thing phenomena that occur in liquids.

With increasing speed and reduced pressure below liquid vapor pressure will cause bubble, this bubble will move accordingly direction of fluid motion, fluid pressure occurs fluid deceleration and increase fluid pressure then cause

the bubble will “explode”. Bubble size starts to increase in size before, the bubble broke when the bubble diameter is maximal. The size of the bubble’s maximum diameter equal to 100 times the core size / bubble size initially, below

bubble size can be shown with mach bubble numbers.

2.4 Concept Framework

Research to be conducted is the experiment done on 1 (one) pump unit and results obtained in a study influenced by the research variable own. The cases that will be observed is the beginning of the bubble in the area impeller and dimension changes are happens with change vibrations that occur, the results are obtained from measurements include vibration response from the casing and observation through a transparent casing previously designed, from

the measurement data will data processing.

3. RESEARCH METHODS

3.1 Place and time

Implementation of this research planned to be carried out at Laboratory of Noise and Vibration, the building of the Mechanical Engineering Department, Faculty of Engineering, University of Sumatra North, Medan with planning

implementation time for ± 8 months.