Electric Thermal Oil Heater/Boiler

| Product capacity: | 30kw-1400kw |

| Working pressure: | 0.1Mpa-3.8Mpa 1bar-38bar |

| Available fuel: | Electric, Electricity |

| Available industries: | For crude oil plants, asphalt, bitumen plant, food industry, textile industry, packaging industries, plywood factories, reactors, refinery oil |

High efficiency, Quick heating, No Pollution, Automatical running electric heating thermal oil to a temperature of 200-350°C

The equipment Uses electricity to heat thermal oil, automatically heating oil up to a temperature of 200°C-350°C. Widely used in asphalt, bitumen, textile, plywood hot pressing, reactor, food fryer, packaging industry, refinery oil, etc

Working Principle: Electricity as an energy source, covert electric energy into heat energy through a flanged immersion heater. The organic heat fluid (hot oil) as a heat transfer medium is circulated in the whole system pushed by the oil pump. And then the using-heat equipment takes heat from the hot oil, which returns to the boiler after the heat exchange. So it is an organic heat circulation system.

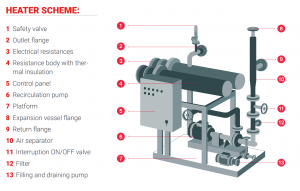

Electric Thermal Oil Heater Consist

The electric heating thermal oil heater consists of the main parts (including the electric heater host, high-temperature oil pump, and Y-shape filter), an expansion tank, a control cabinet, and piping. All the components of the system must work together in harmony for proper performance.

Advantages of Electrical Thermal Oil Boiler

1. Low working pressure

Liquid phase transport heat energy can reduce working pressure and get a high temperature, heat carrier is smaller than the water saturation steam pressure 70 to 80 times, general heating is less than 0.5 Mpa

Electric heating thermal oil heater can reach a temperature of 340°C under low pressure and the heating temperature automatic control. When the heating temperature is up to 300°C, the working pressure is just one-seventieth of the saturated steam pressure.

3. Environmental protection design

The electric heating thermal oil heater is provided with a new electrical heating system, using electricity instead of coal, saving cost, and protecting the environment without pollution.

4. High Thermal Efficiency

Electric heating thermal oil heaters can reach an efficiency of 95%, and achieve stable & even heating and accurate temperature control.

| Model | Rated capacity | Rated pressure | Oil Volume | Dimension(MM) | Hot Oil Pump | Total Power | Weight | Oil Expansion Tank | |||||

| (KW) | (*104kcal/h) | (Mpa) | (L) | L | W | H | Flow(m³/h) | Lift(M) | Power(kW) | Kw | Kg | L | |

| IDM10 | 10 | 0.8 | 0.6 | 15 | 1100 | 500 | 1100 | 6 | 27 | 1.5 | 11.5 | 200 | 100 |

| IDM18 | 18 | 1.5 | 0.6 | 23 | 1600 | 500 | 1250 | 6 | 27 | 1.5 | 19.5 | 200 | 130 |

| IDM24 | 24 | 2 | 0.6 | 28 | 1950 | 650 | 1450 | 12.5 | 30 | 3 | 27 | 350 | 150 |

| IDM36 | 36 | 3 | 0.6 | 48 | 1950 | 650 | 1450 | 12.5 | 30 | 3 | 39 | 350 | 200 |

| IDM48 | 48 | 4 | 0.6 | 48 | 1950 | 650 | 1450 | 18 | 40 | 5.5 | 53.5 | 350 | 230 |

| IDM60 | 60 | 5 | 0.6 | 52 | 1950 | 650 | 1450 | 18 | 40 | 5.5 | 65.5 | 350 | 230 |

| IDM70 | 70 | 6 | 0.6 | 60 | 2150 | 700 | 1750 | 30 | 48 | 7.5 | 77.5 | 550 | 280 |

| IDM90 | 90 | 7.5 | 0.6 | 68 | 2150 | 700 | 1750 | 30 | 48 | 7.5 | 97.5 | 550 | 280 |

| IDM120 | 120 | 10 | 0.6 | 105 | 2200 | 700 | 1880 | 30 | 48 | 7.5 | 127.5 | 750 | 300 |

| IDM150 | 150 | 12.5 | 0.6 | 195 | 2200 | 900 | 1880 | 30 | 48 | 7.5 | 157.5 | 750 | 300 |

| IDM180 | 180 | 15 | 0.6 | 230 | 2200 | 1000 | 1880 | 45 | 48 | 11 | 191 | 1200 | 320 |

| IDM240 | 240 | 20 | 0.6 | 260 | 2300 | 1000 | 1950 | 80 | 38 | 15 | 255 | 1200 | 350 |

| IDM300 | 300 | 25 | 0.6 | 358 | 2800 | 1200 | 2000 | 80 | 38 | 15 | 415 | 1750 | 450 |

| IDM500 | 500 | 40 | 0.6 | 510 | 2800 | 1500 | 2000 | 80 | 38 | 15 | 515 | 1850 | 550 |

| IDM600 | 600 | 50 | 0.6 | 562 | 3000 | 1800 | 2150 | 80 | 38 | 15 | 615 | 1950 | 600 |

| IDM700 | 700 | 60 | 0.6 | 638 | 3000 | 1800 | 2150 | 80 | 38 | 15 | 715 | 2200 | 650 |

| … | … | … | … | … | … | … | … | … | … | … | … | … | … |

| IDM1400 | 1400 | 120 | 0.6 | 2100 | 3600 | 2900 | 2150 | 80 | 85 | 37 | 1437 | 6500 | 1200 |

Workshop

Kawasan Pergudangan Laksana Business Park, Jalan Laksana 6 Blok F 09, Desa laksana Kec. Pakuhaji, Kab. Tangerang, Banten- 15570

PT Indira Mitra Boiler

Ratman Bejo

☎️081388666204

My Website

https://indira.co.id

Specialist Fabrikasi,Thermal Oil Heater,Steam Boiler,Hot Water Boiler

Email: info@indira.co.id

Email: idmratman@gmail.com

https://www.youtube.com/@Ratman_Bejo/videos