How to Install and Test the Furnace Performance Function

Crucible is made of refractory material which is compacted and sintered in the furnace. The induction furnace works on the principle of a transformer with a primary coil flowing AC current from a power source and secondary coil. Secondary coils are placed in the field of the primary coil mahnit will produce induced currents. In contrast to the transformer, the secondary coil is replaced by the fusing material and is designed so that the induced current turns into heat that is capable of melting it. While the higher the frequency of work, the melting capacity will also increase.

Another application derived from vacuum furnaces is Carburizing Vacuum, which is known as Low Pressure Carburizing or LPC. In this system, gases (such as acetylene) are put together with partial pressure to the hot zone against temperatures generally between 1600F and 1950F. After the workpiece matches together with what is desired then it is induced to generally use high-pressure oil or gas (HPGQ) which is nitrogen or helium after that it is quenched together quickly.

Various Functions And Ways Of Working Furnace

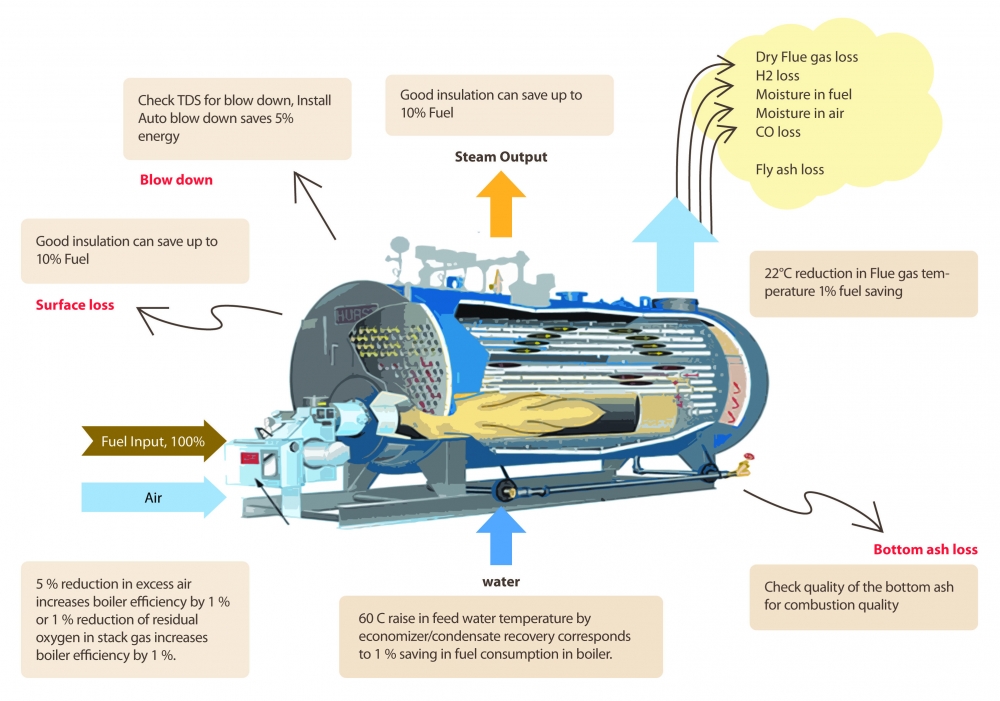

Inside the riser the water undergoes heating and rises to the drum again due to temperature differences. Economiser is a device that is the last water heater before going into the drum. In the economiser the water absorbs the heat of the discharged gas that appears to come from the superheater before being discharged into the atmosphere through the chimney. The boiler needs 6 hours for the cooling system to be temporarily turned off together by blowing air through the fan together accessing the dumper ¼ opens until the pressure exits on the manometer. Dust Collector This section is useful for capturing or collecting ash that is in the combustion flow until the dust is included in the exhaust gases.

the liquid produced from the kitchens as already explained above is then tapped in a preheated ladle. Heating must be done ladle to maintain the temperature of the molten steel does not shrink the capacity of the kudu lodle as needed. From the following ladle molten steel is poured into metal molds to produce ingots or into sand molds to produce steel casting.

Online Selling Good Furnace Burners

One of the benefits of an air heater is to cool the temperature (reduce heat) the flue gas that appears through the stack in order to increase furnace efficiency. Burning oil is mostly more difficult than burning gas. Liquid oil must be converted first into gas (steam) before it can be mixed together with the air and become burned.

Some conversions increase the surface to mass ratio too and it is substantially possible for droplets to absorb heat faster. Atomization can be done together using steam, air or high pressure gas. Although there are several methods that can be used for atomizing fuel oil, steam is most widely used in refineries because it is widely available. Pressure instructions are placed below so that they are easy to see. Blow Off Valve or Tap Down Faucets. Convince the middle faucet and blow down faucet on the ship is fully closed.