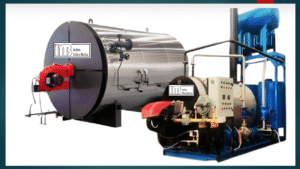

Thermal Oil Heater 100–5000 kW – Energy-Efficient Industrial Oil Heating Solution

1. Introduction to Thermal Oil Heating Systems

Thermal oil heaters, also known as thermal fluid heaters or heat transfer oil boilers, have revolutionized industrial heating processes across various sectors. These systems are designed to efficiently transfer heat using thermal oil as the working fluid, providing a consistent and controlled temperature environment without the need for pressurization.

Capacities range from 100 kW for small-scale operations to 5000 kW or more for large industrial plants. They are widely used in applications requiring indirect heat and temperature stability, such as in chemical processing, food industries, textile manufacturing, oil & gas, and many more.

2. Why Choose Thermal Oil Heaters Over Steam Boilers?

Unlike steam systems, thermal oil heaters operate at lower pressure and still deliver high temperatures up to 350°C. This makes them safer, more energy-efficient, and easier to maintain. Key advantages include:

-

No need for water treatment

-

No corrosion or scaling

-

Minimal maintenance

-

Greater thermal stability

-

High system efficiency (up to 90%)

3. Technical Specification Range (100–5000 kW)

| Parameter | Specification |

|---|---|

| Heat Capacity | 100 – 5000 kW |

| Operating Temperature | Up to 350°C (662°F) |

| Working Fluid | Synthetic/organic thermal oil |

| Pressure | Atmospheric or low-pressure operation |

| Efficiency | 85% – 92% (depending on design) |

| Heat Source | Gas, diesel, dual-fuel, biomass, or electric |

| Control System | PLC / Manual / Digital PID |

The design can be either horizontal or vertical, depending on space availability and application requirements.

4. Applications of Thermal Oil Heaters

4.1. Chemical Industry

Used for reactor heating, distillation, evaporation, and polymerization.

4.2. Food & Beverage Industry

Essential for frying systems, ovens, and heat exchangers.

4.3. Textile Industry

Used in dyeing machines, printing equipment, and drying processes.

4.4. Asphalt & Bitumen Plants

Maintains asphalt fluidity in storage tanks and pipelines.

4.5. Oil & Gas Sector

Used in heat tracing systems, tank heating, and offshore platforms.

4.6. Renewable Energy (CSP Systems)

Serves as the medium for storing and transferring solar heat in concentrated solar power plants.

5. Components of a Typical Thermal Oil Heating System

-

Heater (Main Unit): The heart of the system.

-

Circulation Pump: Maintains oil flow across the system.

-

Expansion Tank: Accommodates oil volume changes during heating.

-

Deaerator Tank: Removes air/gas from thermal oil.

-

Control Panel: Manages temperature, pressure, alarms, and safety interlocks.

-

Piping & Valves: Constructed from high-temperature resistant materials.

6. Fuel Options: Customizable Based on Energy Source

You can choose the fuel source depending on availability and cost-effectiveness:

-

Natural Gas-Fired Heaters

-

Diesel (Light Oil) Heaters

-

Dual-Fuel (Gas + Oil) Options

-

Electric Thermal Oil Heaters

-

Biomass-Fired Heaters (e.g., palm shells, wood chips)

Electric models are preferred for clean energy operations or zones with strict emission regulations.

7. Energy Efficiency & Cost-Saving Features

Modern thermal oil heaters come with economizers, variable speed drives (VSD) for pumps, and intelligent control systems. These features reduce energy consumption and improve system responsiveness.

Comparative Fuel Savings:

Thermal oil heaters can save up to 20–30% energy compared to traditional steam boilers in certain applications.

8. Safety Considerations

Despite the advantages, safety is paramount. Key safety components include:

-

High-temperature cutoff switch

-

Low oil level alarm

-

Oil flow switch

-

Flame failure detection

-

Emergency shutdown mechanism

Certified units follow ASME, CE, ISO, or local industrial codes.

9. Maintenance and Service Life

Thermal oil systems are known for long operational life, sometimes exceeding 15–20 years if maintained properly. Recommended maintenance includes:

-

Annual oil analysis

-

Regular pump inspection

-

Heat exchanger cleaning

-

Control system calibration

10. Customization & Modular Design

Manufacturers often provide custom solutions based on:

-

Heating capacity

-

Space constraints

-

Fuel availability

-

Integration with SCADA/BMS

Modular skid-mounted systems are available for quick installation and relocation.

11. Installation Guidelines

-

Install on level concrete foundation

-

Allow sufficient clearance for servicing

-

Use insulated piping to reduce heat loss

-

Install temperature and pressure gauges in key points

-

Use flexible connections to absorb thermal expansion

12. Environmental Impact and Sustainability

Thermal oil heaters support sustainability by:

-

Lowering emissions compared to steam boilers

-

Enabling heat recovery integration

-

Working with bio-oils or recycled thermal fluids

-

Offering CO₂-neutral operation when using biomass or green electricity

13. Cost Estimate: CAPEX and OPEX

| Capacity (kW) | Typical Price Range (USD) | Fuel Consumption | Maintenance Cost |

|---|---|---|---|

| 100 kW | $10,000 – $15,000 | ~8–10 L/h (Diesel) | Low |

| 1000 kW | $30,000 – $50,000 | ~80–90 L/h | Medium |

| 5000 kW | $90,000 – $130,000 | ~350–400 L/h | Medium/High |

Prices vary based on country, options, and compliance standards.

14. Case Study: 3000 kW Thermal Oil Heater for Textile Factory

A textile factory in Southeast Asia upgraded from steam to a 3000 kW thermal oil heater, resulting in:

-

25% reduction in fuel costs

-

Zero water-related downtime

-

Improved dyeing process consistency

-

ROI within 18 months

15. Frequently Asked Questions (FAQ)

Q: How do I choose the right capacity?

A: Determine your process heat load in kW or kcal/h and add a 10–15% margin for safety.

Q: What is the recommended oil type?

A: Use synthetic or mineral oils designed for thermal applications (e.g., Dowtherm, Therminol).

Q: Can I integrate this with my automation system?

A: Yes. Most units support Modbus, Profibus, or Ethernet for SCADA/BMS integration.

16. Conclusion

If your industrial process requires reliable, high-temperature heating without the downsides of pressurized steam systems, then a Thermal Oil Heater (100–5000 kW) is your best option. With greater energy efficiency, minimal maintenance, and flexible fuel options, thermal oil systems provide a smarter, safer, and more economical solution for modern industries.

Contact Us Today to get a quote or consultation for your specific industrial heating needs. Discover how our thermal oil heaters can optimize your energy costs and production uptime.

PT Indira Mitra Boiler

Ratman Bejo

☎️✔081388666204

My Website

https://burnerstock.co.id

Specialist Fabrikasi,Thermal Oil Heater,Steam Boiler,Hot Water Boiler

Email: idmratman@gmail.com