TYPE OF VALVE (VALVE) MARINE

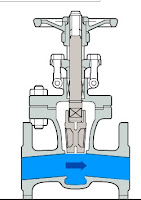

- valve (Valve) is called a gate valve because it contains an element of closure called the gate that stops flowing. The gate door acts like a shutter that separates the inside of the house from the outside or the door that separates the two rooms.

- A vertical disk located on the valve body slides the upper and lower gates at right angles towards the flow in the pipe , closes or opens the valve. The current is blocked by using the valve / valve disc wedge-lock effect.

gate valve image when closed

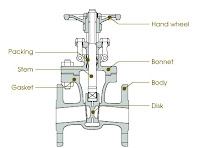

type valve globe valve / valve is usually used to regulate the amount of fluid flow.

- The globe valve is named after its shape. the globe valve shape has an interior partition, and inline valves and outlet centers. This configuration forces changes in flow direction in the form of S.

- The disc blocks the flow of liquid by pressing against the seat on the partition. Concept: force againts.

- by changing the position of the globe disc valve, globe valves can be used for both throttling and for full-on, full-off flow control.

image of valve globe components

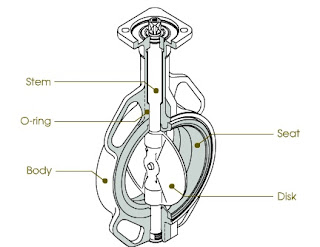

The shape of the insulation is a disk that has a rotating axis in the middle. This type of valveAccording to the design, can be divided into concentric and eccentric. Eccentric has a more difficult design but has a better function than concentric. The simple shape makes it lighter than other valves .

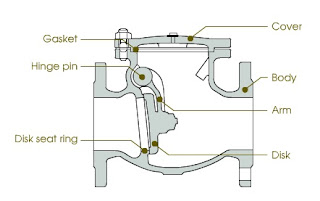

type of valve has a function to drain the fluid only in one direction and prevent the flow in the opposite direction. It has several other types based on its interior like double-plate, swing, tilting, and axial.

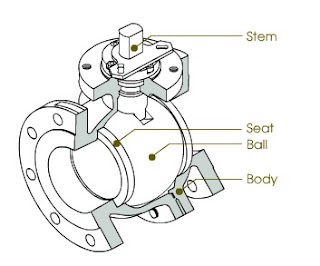

picture of ball Valve components

5. Plug Valve

Like a ball valve, but the inside is not spherical, but a cylinder. Because there is no empty space inside the valve body, it is suitable for fluids that are heavy or contain solid elements such as mud.

- how to determine the type of valve (valve) that will be used based on valve function. type of valve that will only be used for perfect open or close position, gate, butterfly, ball or plug can be used. If the valve will be used to adjust the amount of current (used in conditions between open and close), the globe valve is the most suitable. Different if the function needed is to prevent the return flow, then the check valve is the only choice.

- how to determine the type of valve (valve) that will be used based on valve size. Ball, plug or globe valve is suitable for small sizes, but for large sizes the valve will be very heavy, ineffective and not economical. Replacing it as a butterfly valve is a common route for large valves. But it should also be noted that butterfly valves are not commonly used for high pressure fluids.

Then how do you choose the type of valve (valve) between the gate valve and ball valve which both have the same function? The structure of the ball valve allows the use of soft / resilient seats for the insulating part. With the soft seat, a ball valve can be made with a guarantee of zero leakage that cannot be applied to the gate valve. In addition, the ball valve also has a quarter turn system that allows closing and opening valves quickly. But with the weakness of soft seats that are susceptible to high temperatures, the gate valve has the advantage of being lighter and more economical even though it does not guarantee zero leakage.

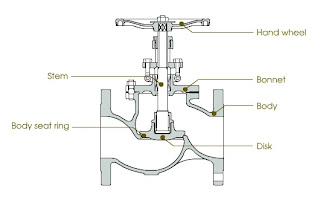

This is where the ability of a pipe engineer is needed who can consider various things in making a decision on which valve to use. In the face of such a thing, usually an engineer will consider lessons from the previous design, both from his own experience or from existing data. The following table is a sample handle for selecting the appropriate valve.