Extend The life of the thermal oil heater

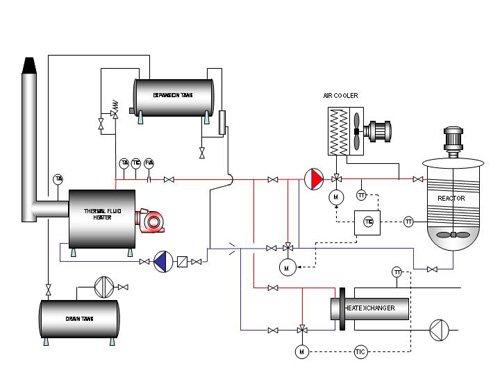

THERMAL OIL HEATER TER OXIDATION, PT Indira Mitra Boiler found a solution to extend the life of the thermal oil boiler / thermal oil heater

One of the reasons that most affects the age of a thermal oil heater is to avoid oxidation in the heating oil. In a simple sense, oxidation is a chain reaction that engages an oil / lubricant so that the properties of the oil / lubricant change. These changes include: change in thickness, to acidity, color, and in the worst case is the appearance of deposits / mud / varnish (scaling on the donding pipe of the thermal oil heater. The use of antioxidant additives can reduce the oxidation process but there are things beyond oil / lubricants which is dominant as a trigger for oxidation,

Triggers for oxidation in the thermal boiler are:

1. Heat. Over heat in chember vessel

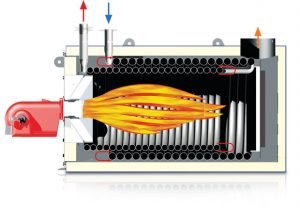

Excessive heat is a trigger for oxidation. The definition of heat here is if the temperature / temperature exceeds the design limit of the thermal oil boiler of the machine itself. Generally, in industrial applications oil / lubricant is maintained at a temperature of 60o Celsius measured in the tank. The general rule, every increase of 10o Celsius from 60o Celsius will reduce the life of oil / lubricant by half. Therefore, it is not recommended that the design rules for thermal fluids burn oil in a chember tank which is silent,Fluid thermal circulation is also recommended with a sepular turbine flas coil design, the design has been checked for a minimum of 3 seconds / 6 meters

To prevent over heating in the body chamber. This design is always used by PT Indira Mitra Boiler to manufacture thermal oil boilers.

2. Trapped air.

Air trapped in oil / lubricant will trigger oxidation along with the temperature rise. Air usually enters the tank through a breather (important hole). As a result of pressure in the return pipe to the tank the foaming phenomenon will occur.As a result air is trapped in the oil / lubricant and triggers oxidation and cavitation / hunting at the heat transfer oil pump.The use of oil / lubricant with good anti-foaming properties can also help reduce air trapping / in the boiler chamber.

TIPS from us, for the heat transfer system (heat transfer system) that uses an oil boiler, at the time of the initial fill make sure no air is trapped into the pipe system with the help of venting in the pipe. This greatly affects the life time / age of the heat transfer oil.

3. Water mixed with oil heater.

In addition to heat and air, water is a trigger for oxidation which is very dangerous. Water usually enters through tank condensation, thermal oil leaks and seal / packing leaks.Water is not only dangerous for oil / lubricant, but also dangerous for lubricated engines.This is due to the lubrication properties of the oil, which decreases resulting in / evaporation / wear on the thermal boiler engine.Water also reduces the ability of the lubricant to be filtered, especially in precision equipment applications that require high filter densities.

TIPS from us, always check the bed at the piping connection, in addition to checking the condition of the oil / lubricant and choose oil / nationality that has the ability to separate themselves with good water and high resistance to water.

4. Metal Catalyst.

Some metals can trigger oxidation, such as copper. Examples of equipment that uses copper are the main bearing and oil cooler.