Heater Deaerators Boiler

Deaeration is the treatment of water to remove water-soluble gases. The gases that dissolve in water are:

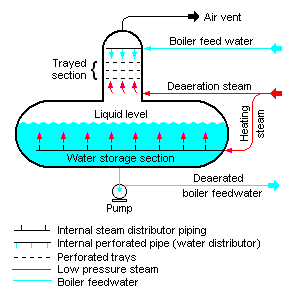

The image for the deaerator is

· Oxygen (O2)

· Carbon dioxide (CO2)

· Hydrogen (H2S)

The effect of CO2 gas in water can cause water to be acidic. If this gas is contained in water, then the water becomes corrosive to the pipe which will form dissolved iron carbonate. In water containing 2-50 ppm CO2, water is corrosive. Gas that accelerates corrosion is oxygen, corrosive which results in holes. To remove dissolved gases such as oxygen, it can be carried out by mechanical or chemical means.

This deaeration method can be divided into two parts, namely:

1. Method of deaeration with the heating system

The heating deaeration process is a separation process that is carried out using mechanical equipment that has been designed in such a way that is used for the work process as desired. The basic principle of deaeration with heating systems is that when the temperature is raised in water, the solubility of the gases will decrease or decrease. So the conditions for maximum deaeration are very dependent on temperature. If the temperature is not as it should be, then the deaeration does not work.

2. Method of deaeration by adding chemical substances (chemical treatment)

Deaeration with the addition of chemical systems is by entering chemical solutions into the water.

Introduction to Deaerator

Deaerator is a device that works to dispose of gases contained in kettle water, after going through the water treatment process. In addition, the deaerator also functions as a boiler pre-heating water before being put into the boiler. Deaerator works based on the nature of oxygen, the solubility in water will decrease with the increase in temperature. The introduction of a deaerator can be seen in the following figure.

Deaerator

This deaerator tool consists of two drums where the smaller drum is a preheating place and the disposal of gases from the kettle water material, while the larger drum is a reservoir of kettle water material that falls from a smaller drum on top. In smaller drums there is a spray nozzle which functions to spray kettle water material into fine water droplets so that the process of heating and discharging gases from kettle water material is more perfect. Also on smaller drums a vent channel is provided so that gases can be wasted (along with steam) into the atmosphere.

The main element in determining the success of this process is the physical contact between the kettle water material and the heat supplied by steam. Some things that need to be considered in the deaerator process are:

· The amount of condensate water flow

· Amount of flow of kettle water material

· Pressure in a deaerator

· Water level in a deaerator

If the deaerator cannot work properly, it can adversely affect the feed water system, condensate system, and will also increase the use of chemicals. To achieve good deaerator efficiency there are several things that need to be considered, namely:

· Maintain the highest temperature and pressure as possible according to the design

· Make sure the steam / steam out / venting from the deaerator that oxygen and gases that are not condensed come out

· Inspect the inside of the deaerator to make sure all components are not damaged

Main Parts of Deaerator

To support the deaerator’s work, the deaerator needs to be equipped with measurement instruments, which are useful for monitoring the operation or work of the deaerator itself. The picture below shows the main parts of the deaerator and the several measurement instruments that complete them.

Deaerator Component

Types of Deaerators

The types of deaerators that are often encountered are:

a.Deaerator Spray type

This deaerator is used when feed water needs to be heated first by using steam as a heater. As Figure II.3 below, the steam that enters the flow deaerator breaks the water into small debris which causes the water-soluble gases to be forced out so that the oxygen concentration in the water drops.

Spray type deaerator

b.Deaerator type Vacuum The working mechanism of a vacuum deaerator is that gases that dissolve in water are removed using a steam ejector or or with a vacuum pump, to obtain the required vacuum, the vacuum deaerator mechanism can be seen in the following figure II.4. The size of the vacuum depends on the temperature of the water, but usually 730 mmHg.

Vacuum Deaerator type

c.Deaerator Tray type

In the tray type deaerator as seen in figure II.5 below, maximizing the bulkhead (Tray) as a medium to enlarge the falling space from the water so that the water molecules will be separated from one another, so the tray on this type of deaerator is to force water molecules to spread so as to facilitate air release.